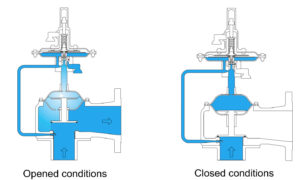

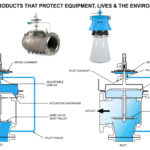

The use of Pilot Operated Relief Valves permits an operating pressure closer to the maximum allowable working pressure of the tank. High operating pressures reduce evaporation and total venting volume, thereby reducing product loss. cost of processing emissions, protecting the environment and promote safety.

Assentech

Assentech are accredited by a UKAS certified body to ISO 9001, ISO 14001, OHSAS 18001 and working towards Fit for Nuclear

Why choose us?

Assentech Engineers use a comprehensive test regime. We are confident that our technical and scientific knowledge of how a breather vent operates, will ensure that we can assist your site to achieve maximum efficiency and legislative compliance.