OUR CHALLENGE TO TANK FARM FACILITIES MANAGEMENT

Meeting Compliance and Maximum Profitability

- PLEASE LIST 4 REASONS WHY BREATHER VENTS ARE FITTED TO YOUR STORAGE TANKS?

- WHAT STANDARD ARE YOUR VENTS DESIGNED, TESTED AND BUILT TO?

- CAN YOU DEMONSTRATE THAT YOUR VENTS ARE WORKING WITHIN THE DESIGN LIMITS OF YOUR STORAGE TANKS?

- HOW OFTEN SHOULD THIS EQUIPMENT BE INSPECTED?

- HOW OFTEN SHOULD THIS EQUIPMENT BE SERVICED?

- DO YOU KNOW WHAT ASPECTS OF VENT CALIBRATION AND TESTING KEEP YOU ON THE RIGHT SIDE OF THE LAW?

Managing ageing plants is never easy. Reduced budgets, scarce labour resource and tightening legislative compliance makes tank farm management very challenging.

Well maintained facilities rarely suffer unplanned outages, fines and the associated bad press involving the

Environment Agency and/or The Health and Safety Executive (HSE). Furthermore, their standard of stored product remains high, resulting in minimal production issues and premium quality.

It is an unfortunate reality that most catastrophic incidents follow a number of ignored near misses, tolerance of ineffective equipment and poor product/process knowledge.

Keeping plants in excellent shape is imperative and will ensure a safe working environment. Companies also benefit from meeting compliance, achieving minimal downtime and maximum profitability.

Please list 4 reasons why breather vents are fitted to your storage tanks?

A) Reduce vapour losses which reduces the volatility of the stored product

B) Reduce water ingress through condensation, causing tank corrosion and product contamination

C) Prevent flammable vapour clouds circulating around the facility.

D) Reduce toxic vapours affecting the health of operators and surrounding areas.

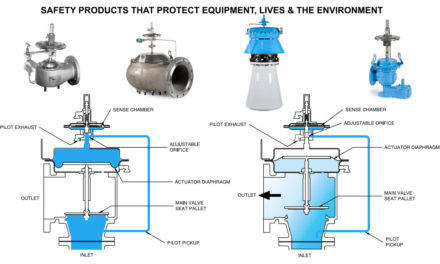

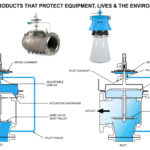

What standard are your vents designed, tested and built to?

API2000, ISO28300, ISO14015.

If you or your team want to know more about Tank Venting or get up to speed with the latest changes to API2000 and ISO28300 we will be happy to run a technical seminar or lunch and learn session for you. We make no charge for the sessions for end users or groups of 5 or more people.

Assentech has come up with a checklist to help buyers make the right (and safe) choices when buying breather valves click here for details

Can you demonstrate that your vents are working within the design limits of your storage tanks?

Hopefully yes. This is a quick and easy calculation using publicly available software programmes and manufacturers literature.

How often should this equipment be inspected?

Subject to the application generally every 6 months or 12 Months. Heavy fouling or corrosive applications may be more frequent.

How often should this equipment be serviced?

Strictly subject to application criteria but usually at some point between 12 months for highly corrosive or heavy fouling applications to 36 months for clean applications.

Do you know what aspects of vent calibration and testing keep you on the right side of the law?

Agreed scheme of examination. test and calibration certificates that are less than 3 years old that match site application limits of the tank.

Assentech has come up with a checklist to help buyers make the right (and safe) choices when buying breather valves click here for detail

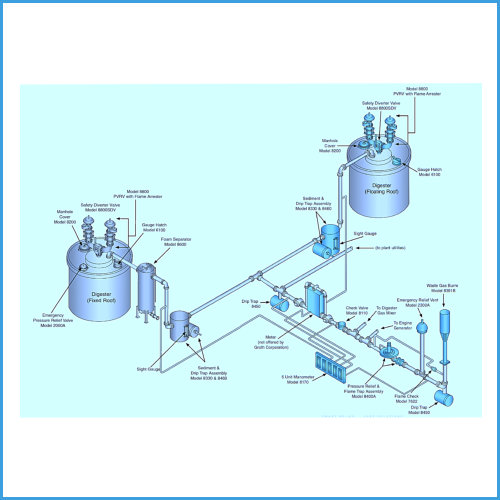

Assentech supply, install and service full range of storage tank and fluid transfer equipment in the UK and Europe.

Some of our customers testimonials

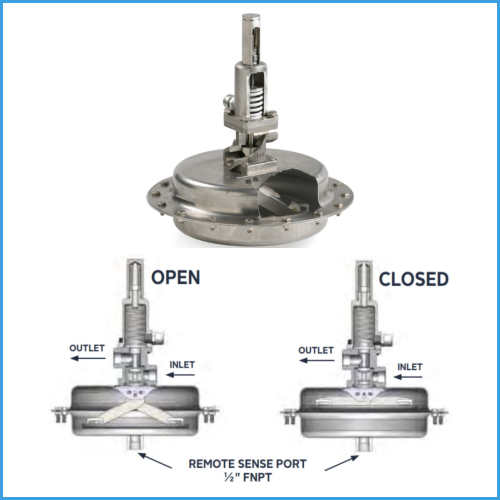

Assentech- pilot operated pressure relief valves service and calibration

Assentech- pilot operated pressure relief valves service and calibration

After conducting a Third Party Witness Inspection, I was most impressed with Ewart and his team, their professionalism, and product knowledge I found to be excellent.

Ian Johnston

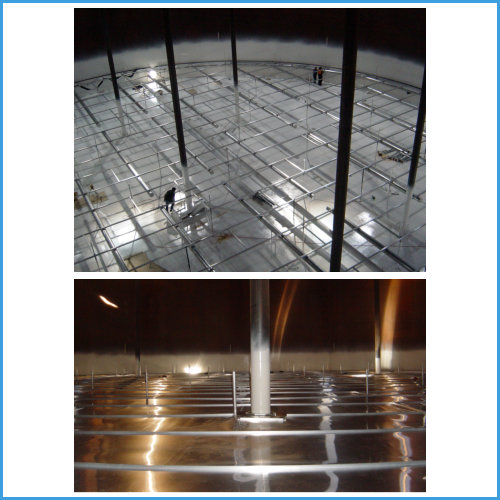

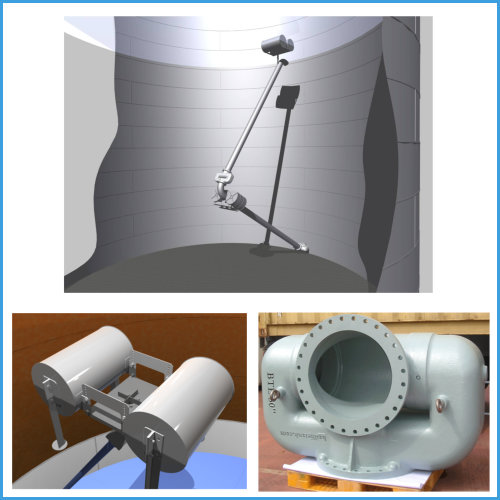

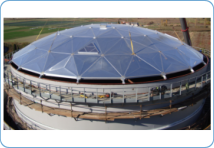

Assentech- Geodesic Dome Installation

Assentech- Geodesic Dome Installation

Assentech were subcontracted to assemble and install a 25m geodesic dome for Shaft G on the Lee Tunnel project. My experience with Assentech from pre-contract through to assembly has been very positive. Unlike other subcontractors I have experienced on this project, Assentech had a very positive attitude to producing the level of documentation required for a project of this scale. Leading to a high quality pre construction packaged approved in a timely manner. The communication regarding the manufacturing process was first class allowing us to easily plan our works and prepare the site. Dome assembly was carried out very efficiently and completed to programme. The task was correctly resourced and well supervised. The work force had a positive attitude and carried out the task safely. In summary from my perspective it has been a very easy subcontract to manage with a high quality finished product.

Robert Colthorpe

Assentech wins supplier excellence award from Eastman Chemicals

Assentech wins supplier excellence award from Eastman Chemicals

We were extremely pleased with the level of service and professionalism demonstrated by Assentech, right from our initial enquiry, through delivery and post installation. As a recipient of only two of these awards made by Eastman Chemical Company in the UK, based on performance in 2014, Assentech are rightly proud of their achievements.

Assentecha-IFR Installations at Vopak, Teesside

Assentecha-IFR Installations at Vopak, Teesside

As you said “you delivered what it said on the tin”. On time and on budget. Your up front engineering to determine the suitability of your product for our application was second to none, i have not seen anyone else in the industry pay as much attention to detail before you get the purchase order number as Assentech.

Garry Lee

Assentech–IFR Installations at Navigator Terminals

Assentech–IFR Installations at Navigator Terminals

Assentech have supported our Navigator Terminal (formerly known as Vopak Teesside) on two important ~

projects by providing technical assistance and supplying and fitting a total of 11 Internal floating roofs. Both projects have been completed on schedule and on budget. Assentech have provided an excellent level of experience and front end engineering support with high quality drawings and documentation. Their specialist on site labour have worked collaboratively with us and Assentech have proven to be open, honest and flexible partners.

We have experience of both their Heavy Duty Pontoon type and Full Contact IFR’s and we continually monitor operation and performance of all lFR units Installed on site and consider the Assentech supplied Matrix brandto be the best in the market with exceptional build quality and rigidity. Our clients have inspected the installations and have always remarked upon the build quality and have been impressed with their strength in fully supporting up to four people without noticeable deformation. The design and construction of their stainless steel shoe seals continue to prove to operate excellently with no noticeable reduction in performance or flotation ability over the time since Installation.

Assentsch have proven to be extremely competitive on price and their installation and inspection activities have always been thorough. Navigator therefore have no hesitation in recommending Assentech to other companies considering their services.

Brian Beddow