Take a deep breath

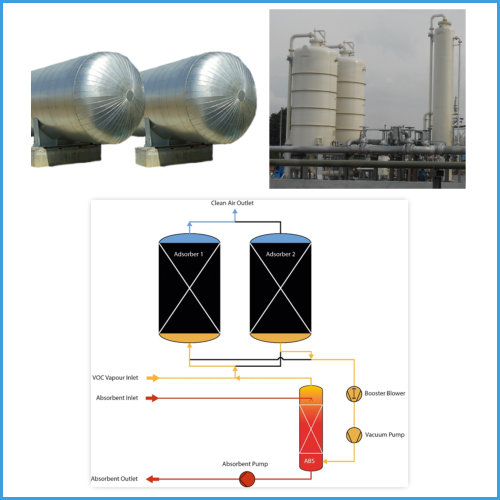

With increased focus by authorities on storage tank conservation and in particular breather vent leak tightness we at Assentech are pleased that our unique approach to servicing vents at customer premises is being recognised as making a positive difference for the environment.

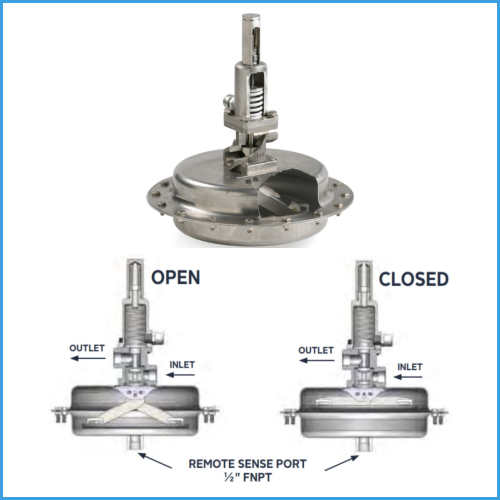

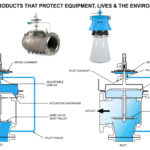

Breather valves “Conservation vents” perform an important role in the control of emissions to the atmosphere, in addition to their important role as safety / emergency valves. Breather vent performance is all about keeping the tank closed to the environment for the widest pressure band permitted by the tank design limits.

We have found some carbon steel emergency vents stop sealing after 2-3 years because of rust scale build up behind the sealing diaphragm. From a customer’s point of view this then raises concerns regarding their emissions, loss of product and a tangible impact on their unexpected costs as they have to resolve the issue through increased maintenance or un-planned equipment change-outs.

It’s clear to us that there’s a race to the bottom in the industry by some manufacturers seeking to be the cheapest competitor at the cost of product integrity.

Conversely, Groth carbon steel emergency vents have stainless steel seat rings and pallets and air cushion seating to ensure leak tightness throughout the whole life of the breather vent. From Assentech Rapid Responses’ experience, these products far out-perform their standard rivals; providing the best long-term value for money and supporting companies to meet their desired and regulatory emissions and safety targets.

With potentially thousands of pounds wasted in lost production, emissions penalties, lost product quality Tank Farm operators need to be fully appraised. All of the pitfalls can be avoided simply by a 5 minute look at the specification of the vents supplied by the vendor and asking some key questions such as; does the manufacturer supply individual vent leak test certification or is it batch? If it’s a batch, how does the customer know their specific valve actually meets the API2000 standards? It’s vital on a vent located in any exposed position that all parts critical to sealing functionality are at least made from non-corroding parts. It is wise to consider that a £100 saved now will cost many thousands to the operator in years to come should the equipment not be properly specified to ensure long-term reduced emissions, tank integrity and overall longevity and minimal maintenance.

Whether Assentech is chosen as the preferred supplier or not, more important is that everyone works towards a Clean Air, improved longevity of their plant and, ultimately the protection of the valuable people who work there. Assentech can offer tank sizing advice and access to their sizing programmes, together with honest and straightforward advice for a variety of process and storage equipment. Contact the team on 01726 844707 or e-mail info@assentech.co.uk.

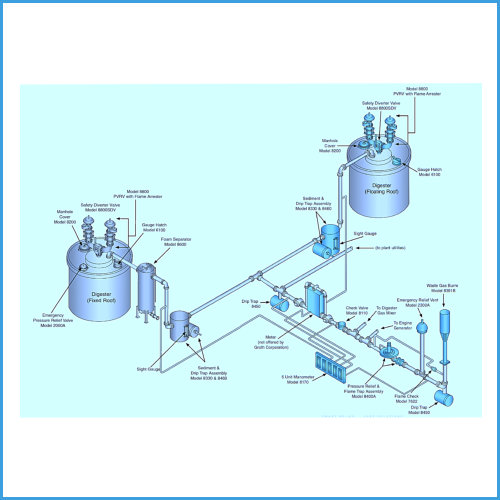

Assentech supply, install and service full range of storage tank and fluid transfer equipment in the UK and Europe.

Assentech- pilot operated pressure relief valves service and calibration

Assentech- pilot operated pressure relief valves service and calibration

After conducting a Third Party Witness Inspection, I was most impressed with Ewart and his team, their professionalism, and product knowledge I found to be excellent.

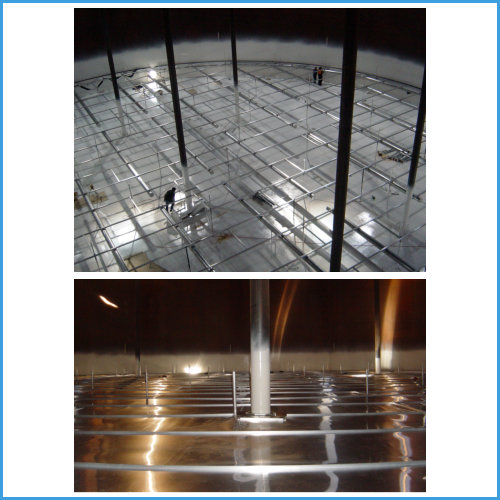

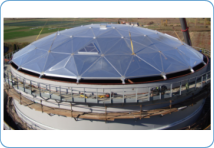

Assentech- Geodesic Dome Installation

Assentech- Geodesic Dome Installation

Assentech wins supplier excellence award from Eastman Chemicals

Assentech wins supplier excellence award from Eastman Chemicals

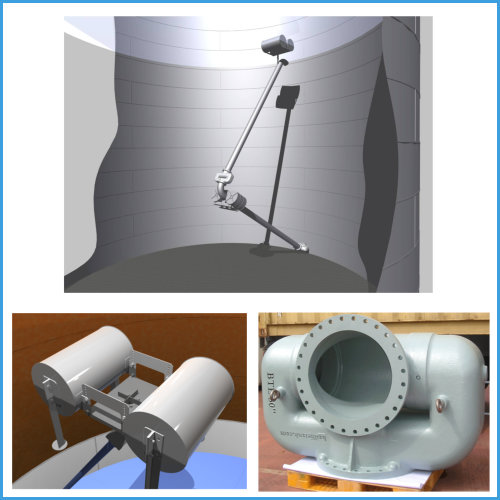

Assentech–IFR Installations at Vopak, Teesside

Assentech–IFR Installations at Vopak, Teesside

As you said “you delivered what it said on the tin”. On time and on budget. Your up front engineering to determine the suitability of your product for our application was second to none, i have not seen anyone else in the industry pay as much attention to detail before you get the purchase order number as Assentech.

Assentech–IFR Installations at Vopak, Teesside

Assentech–IFR Installations at Vopak, Teesside

Assentech have supported our Navigator Terminal (formerly known as Vopak Teesside) on two important ~

projects by providing technical assistance and supplying and fitting a total of 11 Internal floating roofs. Both projects have been completed on schedule and on budget. Assentech have provided an excellent level of experience and front end engineering support with high quality drawings and documentation. Their specialist on site labour have worked collaboratively with us and Assentech have proven to be open, honest and flexible partners.

We have experience of both their Heavy Duty Pontoon type and Full Contact IFR’s and we continually monitor operation and performance of all lFR units Installed on site and consider the Assentech supplied Matrix brand to be the best in the market with exceptional build quality and rigidity. Our clients have inspected the installations and have always remarked upon the build quality and have been impressed with their strength in fully supporting up to four people without noticeable deformation. The design and construction of their stainless steel shoe seals continue to prove to operate excellently with no noticeable reduction in performance or flotation ability over the time since Installation.

Assentsch have proven to be extremely competitive on price and their installation and inspection activities have always been thorough. Navigator therefore have no hesitation in recommending Assentech to other companies considering their services.