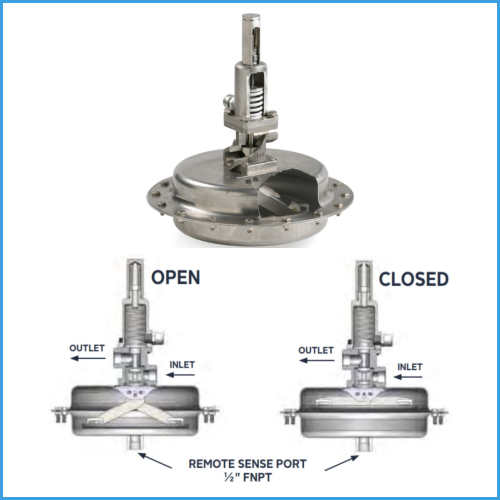

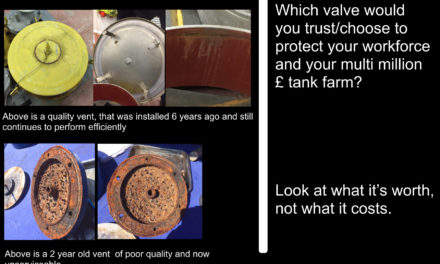

What does a cheap breather valve/pressure vacuum relief valve look like?

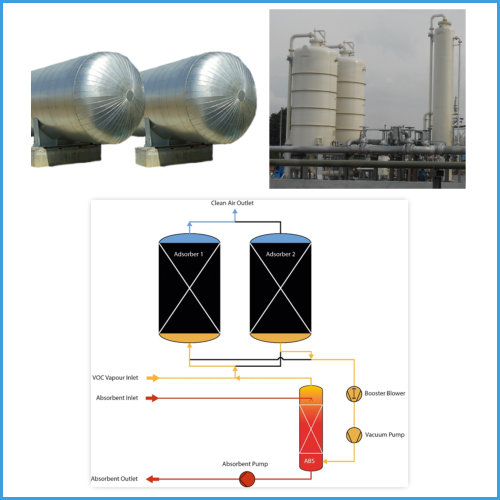

In an economically competitive environment, it is important to adopt a storage tank venting approach which provides the maximum degree of safety followed by minimum product losses.

“30% of storage tank accidents were caused by human errors including poor operations and maintenance. Other causes were equipment failure, sabotage, crack and rupture, leak and line rupture, static electricity, open flames etc. Most of those accidents would have been avoided if good engineering have been practised.”Journal of Loss Prevention in the Process Industries /Volume 19, Issue 1/Pages 51-59.

What does a cheap breather valve/pressure vacuum relief valve look like? :

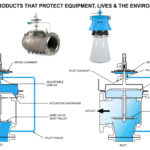

- It may be Welded not Cast

- An O Ring may be used instead of machined and lapped seat

- Potentially, a poor quality diaphragm made of substandard materials is used instead of high-quality FEP

- A flat pallet without a seat cushion (often built up with poor quality gaskets in an attempt to gain a seal) instead of a quality air cushioned pallet (with superior leak tightness).

- Hacked lead weights instead of designed weight packs leading to an imbalance of load on the pallet = more leak propensity

- Not individually API 2000 compliant (certified and leakage tested to the standard)

So, with the above in mind, what is the consequences of using cheap low-quality breather valves?:

- Saving short-term £xx but increasing fugitive emissions. Potentially risking the life of the operators, polluting the surrounding environment, compromising product quality and potentially resulting in compliance sanctions/litigation etc.

- Saving short-term £xx but risking precious tank and site safety: Poor design and manufacturing quality can make valves unpredictable.

- Breather valve failure through a loading/unloading operation could present a risk of damaging the tank with significant cost and shut-down implications.

- Finally, Poorer quality products will degrade more quickly over time than those of their higher calibre counterparts leading to long-term cost ineffectiveness.