⦾ Loading Arms Service

⦾ Loading Arms Service

Loading arms are critical logistical components in the safe transfer of hazardous fluids. They must be light to handle, leak tight, reliable but above all safe. For many of our customers their loading arm is used daily for loading/off loading stock media that is critical for the smooth running and profitability of their business. In many cases there is no alternate means of fluid transfer if the arm comes out of service. To function efficiently and safely the arm must be balanced with free moving but tight sealing swivels. The coupler and/or control valve must be simple and safe to activate.

Safe management of the loading arm requires that it is maintained and inspected regularly. The simple construction and good design of loading arms regularly results in them being excluded from routine maintenance programs. This is often a conscious decision by operators who cannot allow the arm to be out of service for more than a few hours.

Many arms are hard connected to the tanker while loading and drivers are fallible. A drive off can result in difficult to repair damage to pipe work and control valves. This damage usually renders valves inoperable resulting in massive loss of containment with catastrophic consequences for personnel and the environment.

Swivel seals have a service life counted in years as long as it is compatible with the process and lubricated regularly with the right grease.

Assentech can offer a maintenance program to ensure the arm is reliable and safe. Service inspections can reveal potential problems such as seals beginning to weep or seize. Our focus will be on the performance of the arm and how we can keep it in service, leaving the customer to focus on manufacturing and logistics. We offer the following maintenance:-

- Level 1 (Service Code LA01):

Service or repair individual swivels at the customers premises but not requiring total removal of the arm.

- Level 2 (Service Code LA02):

Removal of the arm and full refurbishment of the swivel assemblies and pressure test on site.

- Level 3 (Service Code LA03):

Serviced at Assentech premises and includes the capability to replace sections of loading arm if required.

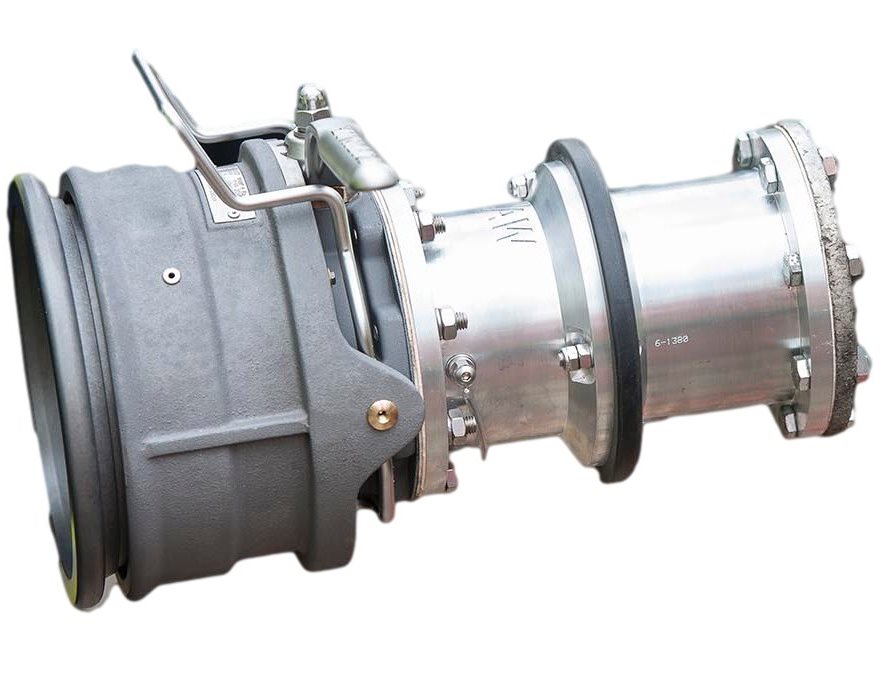

⦾ Break-away Couplers Service

⦾ Break-away Couplers Service

Assentech supply and service KLAW break-away couplings to protect a loading facility from the aforementioned consequences of a drive off. The break-away coupling is a critical safety device and requires periodic maintenance inspections. This coupling has the potential to be used as a fundamental safety mechanism for all Tier 1 COMAH (Control of Major Accidents and Hazards) sites in the UK. It is a key shield to protect the business from lost production, the environment from uncontrolled spillages and workers from explosive hazardous fluids.

Transfer of hazardous chemicals requires an engineered solution that ensures personnel remain safe during loading. The key benefit of an engineered coupler over a bolted flange connection is speed of activation. There remains applications where bolted flanges are still the standard solution due to the dangerous nature of media being transferred, however Assentech can offer a solution for almost every application using high integrity quick release couplers. Far safer than bolted flanges these devices can offer dry break operation and key coding that will ensure mismatching of arms/hoses. The Epsilon coupler is a peerless design offering unparalleled levels of safety with all the benefits of quick release functionality.

We have accumulated a vast amount of experience on the application of break-away couplings which provide an engineered self sealing weak link in the loading arm. It is essential that the coupling is robust enough to withstand the rigours of daily loading procedures but designed to activate before damage occurs to the facility.

Assentech are the only approved KLAW service and maintenance (KTAC) provider and we can offer a support package to ensure continued performance and reliability.

- Level 1 (Service Code BC01):

Site inspection. This is to check if the break stud tensions are holding up .

- Level 2 (Service Code BC02):

Replacement of any worn parts and routine change-out of fatigued components.

This includes replacement of old or fatigued pins and seals. Followed by pressure test and certification

⦾ Hose Leakage Testing-Certification Service

⦾ Hose Leakage Testing-Certification Service

Assentech offers hose leakage testing. Act now to avoid unplanned outages and increase safety for your operators.

The hose test parameters we test to confirm the hose integrity :

• Pressure Test

• Elongation Checks

• Durometer Recordings

• Visual Inspection

• Certification

All the above tests Completed at the customers premises.

Assentech have a wealth of experience in tanker loading and offloading applications, as well as servicing tanker loading equipment and customer fabrications, Assentech also supply, design and install top and bottom loading systems and loading gantries and we are proud to be UK distributors for OPW Fluid Transfer.

Some of our customers testimonials

Assentech- pilot operated pressure relief valves service and calibration

Assentech- pilot operated pressure relief valves service and calibration

After conducting a Third Party Witness Inspection, I was most impressed with Ewart and his team, their professionalism, and product knowledge I found to be excellent.

Ian Johnston

Assentech- Geodesic Dome Installation

Assentech- Geodesic Dome Installation

Assentech were subcontracted to assemble and install a 25m geodesic dome for Shaft G on the Lee Tunnel project. My experience with Assentech from pre-contract through to assembly has been very positive. Unlike other subcontractors I have experienced on this project, Assentech had a very positive attitude to producing the level of documentation required for a project of this scale. Leading to a high quality pre construction packaged approved in a timely manner. The communication regarding the manufacturing process was first class allowing us to easily plan our works and prepare the site. Dome assembly was carried out very efficiently and completed to programme. The task was correctly resourced and well supervised. The work force had a positive attitude and carried out the task safely. In summary from my perspective it has been a very easy subcontract to manage with a high quality finished product.

Robert Colthorpe

Assentech wins supplier excellence award from Eastman Chemicals

Assentech wins supplier excellence award from Eastman Chemicals

We were extremely pleased with the level of service and professionalism demonstrated by Assentech, right from our initial enquiry, through delivery and post installation. As a recipient of only two of these awards made by Eastman Chemical Company in the UK, based on performance in 2014, Assentech are rightly proud of their achievements.

Assentech-IFR Installations at Vopak, Teesside

Assentech-IFR Installations at Vopak, Teesside

As you said “you delivered what it said on the tin”. On time and on budget. Your up front engineering to determine the suitability of your product for our application was second to none, i have not seen anyone else in the industry pay as much attention to detail before you get the purchase order number as Assentech.

Garry Lee

Assentech-IFR Installations at Navigator Terminals

Assentech-IFR Installations at Navigator Terminals

Assentech have supported our Navigator Terminal (formerly known as Vopak Teesside) on two important projects by providing technical assistance and supplying and fitting a total of 11 Internal floating roofs. Both projects have been completed on schedule and on budget. Assentech have provided an excellent level of experience and front end engineering support with high quality drawings and documentation. Their specialist on site labour have worked collaboratively with us and Assentech have proven to be open, honest and flexible partners.

We have experience of both their Heavy Duty Pontoon type and Full Contact IFR’s and we continually monitor operation and performance of all lFR units Installed on site and consider the Assentech supplied Matrix brandto be the best in the market with exceptional build quality and rigidity. Our clients have inspected the installations and have always remarked upon the build quality and have been impressed with their strength in fully supporting up to four people without noticeable deformation. The design and construction of their stainless steel shoe seals continue to prove to operate excellently with no noticeable reduction in performance or flotation ability over the time since Installation.

Assentsch have proven to be extremely competitive on price and their installation and inspection activities have always been thorough. Navigator therefore have no hesitation in recommending Assentech to other companies considering their services.

Brian Beddow